CEMS-PRE422- Temperature Pressure Flow Integrated Analyzer for Emission Monitoring

CEMS-PRE422- Temperature Pressure Flow Integrated Analyzer for Emission Monitoring

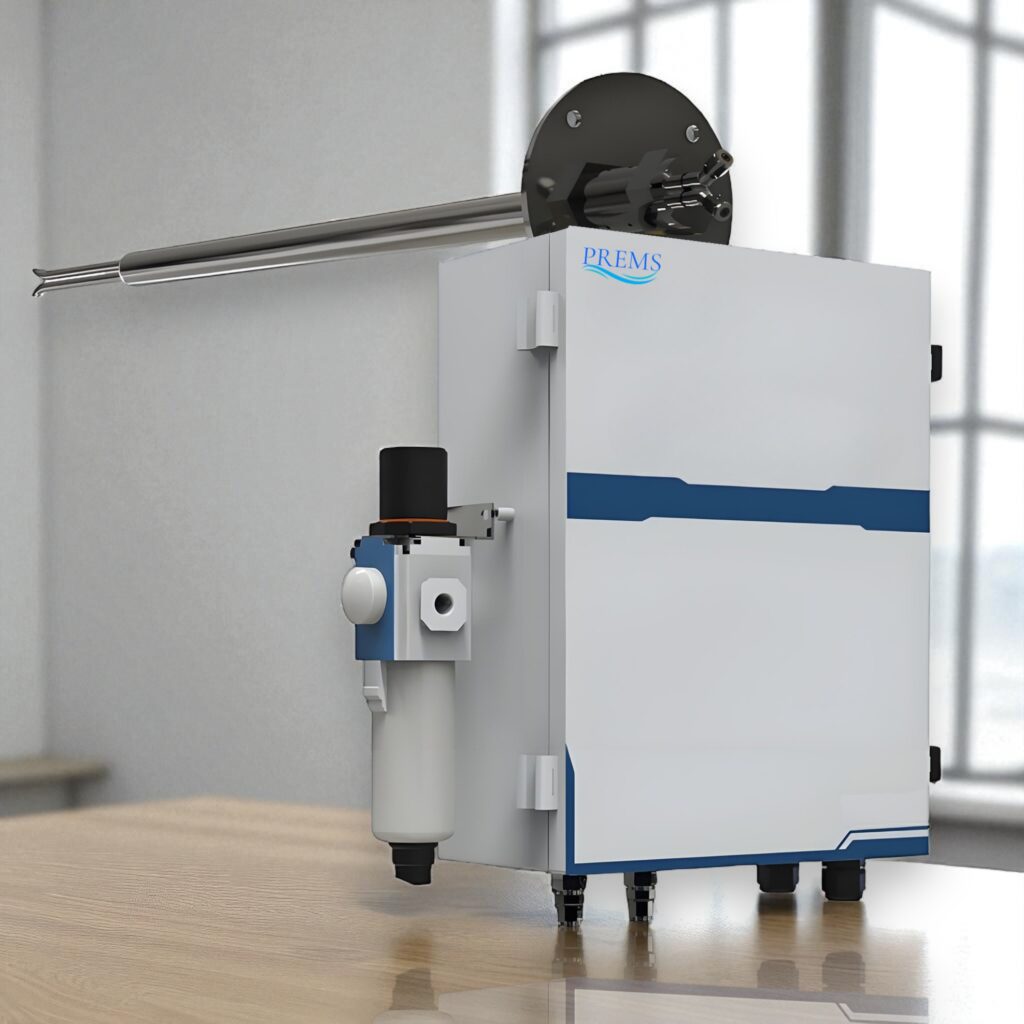

CEMS-PRE422 is an integrated analyzer for measuring flue gas flow, pressure, and temperature in Continuous Emission Monitoring Systems (CEMS). Designed for harsh industrial environments, it offers high accuracy, automatic zero calibration, and reliable performance, helping industries comply with environmental regulations and optimize operational efficiency.

CEMS-PRE422 – Temperature Pressure Flow Integrated Analyzer for Emission Monitoring

The CEMS-PRE422 is a high-performance integrated analyzer designed for accurate and reliable measurement of flue gas flow velocity, pressure, and temperature in harsh emission environments. This analyzer is tailored for Continuous Emission Monitoring Systems (CEMS), combining multiple sensing technologies into a single intelligent unit.

Engineered for demanding industrial conditions such as high dust, high temperature, high humidity, and corrosive atmospheres, the CEMS-PRE422 ensures stable long-term operation while complying with national and international emission monitoring standards.

Key Features and Advantages

-

All-in-One Design: Integrates S-type pitot tube, RTD sensor, differential and absolute pressure transmitters, and self-cleaning back-blowing mechanism.

-

Real-Time Monitoring: Provides continuous and precise measurement of gas flow rate, static/dynamic pressure, and temperature.

-

Robust Performance: Withstands extreme temperatures (up to 800°C) and harsh flue gas compositions.

-

Automatic Zero Calibration: Supports both manual and automatic zero-point adjustments.

-

Flexible Installation: Supports DN60 flange mounting and customizable probe lengths to suit various duct configurations.

Analyzer Characteristics

The CEMS-PRE422 Temperature Pressure Flow Integrated Analyzer includes:

-

S-type pitot tube for measuring flow velocity via differential pressure.

-

Thermal resistance element (RTD) for accurate flue gas temperature detection.

-

Pressure and differential pressure transmitters for precise pressure readings.

-

Self-cleaning system with automatic/manual back-blowing for zero-point recalibration.

-

Smart interface supporting 4–20mA analog output and RS232 communication.

This compact unit reduces installation complexity, increases reliability, and ensures high-quality emission data for environmental compliance.

Technical Specifications

| Project | Indicators |

|---|---|

| Measurement Principle | S-type Pitot Tube Differential Pressure Principle |

| Measuring Range | – Velocity: 0 ~ 15.5–40 m/s

– Differential Pressure: 0 ~ 500–1000 Pa – Temperature: 0 ~ 300–800°C – Pressure: -10 ~ +10 KPa |

| Accuracy | – Velocity: ≤±3% Full Scale (F.S) – Pressure: ≤±3% F.S – Temperature: ≤±3% F.S |

| Response Time | ≤ 1s (T₉₀) |

| Flue Gas Temperature Range | -40°C ~ 500°C |

| Back-Blowing Zero Adjustment | Manual Zero & Automatic Zero |

| Communication Interface | 3 Channels 4–20 mA Analog Output, Optional RS232 Interface |

| Installation Method | Probe Type, Flange DN60 Installation |

| Power Requirements | AC 220V, 50Hz, 50W |

| Operating Temperature | – Host Unit: -20°C ~ 55°C – Probe: < 180°C |

| Dimensions | Pitot Tube: 0.6m, 1m, 1.2m, 1.5m (regular sizes; customizable upon request) |

| Instrument Weight | 10 kg |

Typical Applications

-

Emission Monitoring in Industrial Plants: Perfect for CEMS in power plants, cement factories, and metallurgy.

-

Environmental Protection Systems: Enables compliance with environmental regulations through reliable gas parameter monitoring.

-

High-Temperature, High-Dust Operations: Maintains accuracy in challenging operating environments with minimal maintenance.

Conclusion

The CEMS-PRE422 Temperature Pressure Flow Integrated Analyzer is the ideal solution for modern emission monitoring needs. Its integrated design, high accuracy, and automatic zero calibration features make it a smart and reliable choice for industries seeking environmental compliance with reduced downtime and maintenance.

CEMS-PRE400 Ultrasonic Flowmeter – Advanced Solution for Accurate Gas Flow Measurement

CEMS-PRE350 Heat Tracing Sampling Compound Pipe – The Ultimate Solution for Environmental Monitoring