CEMS-PRE350 Heat Tracing Sampling Compound Pipe – The Ultimate Solution for Environmental Monitoring

CEMS-PRE350 Heat Tracing Sampling Compound Pipe – The Ultimate Solution for Environmental Monitoring

Environmental monitoring systems like CEMS (Continuous Emission Monitoring Systems) are crucial for accurately tracking harmful emissions in various industrial processes. One key component of these systems is the CEMS-PRE350 heat tracing sampling compound pipe, designed specifically to ensure reliable sampling even under harsh environmental conditions. With its advanced corrosion-resistant materials and high-temperature capabilities, this product is indispensable for industries needing precise and durable solutions.

Introduction

Environmental monitoring systems like CEMS (Continuous Emission Monitoring Systems) are crucial for accurately tracking harmful emissions in various industrial processes. One key component of these systems is the CEMS-PRE350 heat tracing sampling compound pipe, designed specifically to ensure reliable sampling even under harsh environmental conditions. With its advanced corrosion-resistant materials and high-temperature capabilities, this product is indispensable for industries needing precise and durable solutions.

Product Overview

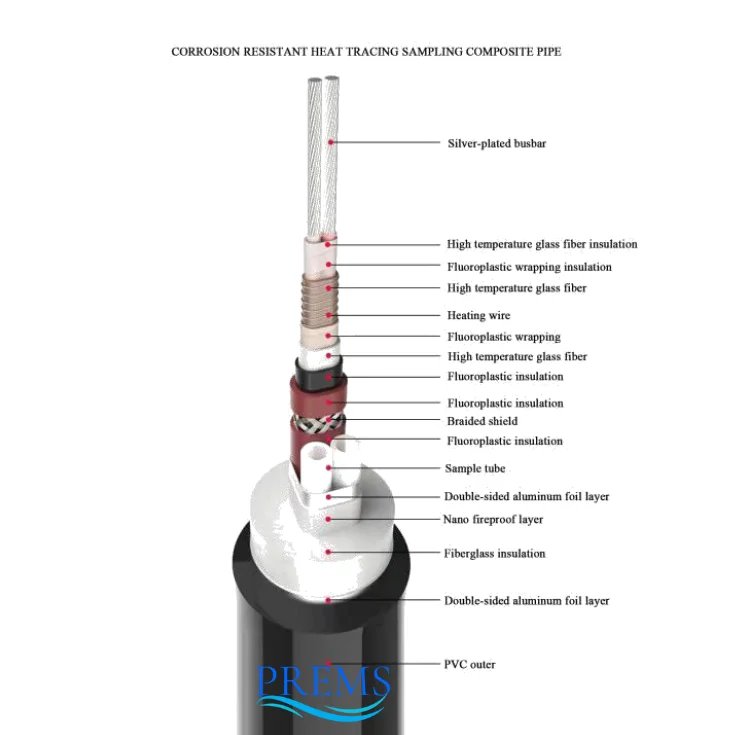

The CEMS-PRE350 heat tracing sampling compound pipe is a robust, multi-layered pipe system built to withstand extreme environments. Designed for high-performance emission monitoring systems (CEMS/VOCs), it is composed of reinforced explosion-proof, corrosion-resistant materials such as PTFE, PFA, FEP, PVDF, and 316L stainless steel. It also features advanced insulation layers like double-sided aluminum foil, high-temperature glass fiber, and a nano fireproof layer, all encased in a protective PVC sheath.

Key Features

1. Exceptional Corrosion Resistance

The sampling compound pipe is engineered to resist corrosion from a wide range of acids, alkalis, and other aggressive chemicals. With a pressure resistance of up to 0.8 MPa without leakage, this pipe can handle the most demanding industrial environments.

2. High Temperature and Environmental Durability

The CEMS-PRE350 can operate effectively in extreme weather conditions. When exposed to temperatures as low as -20°C and wind speeds reaching 15 m/s, the internal sampling temperature remains stable at 40-200°C, ensuring uninterrupted performance.

3. Reliable Long-Term Operation

Designed for long-lasting operation, the sampling pipeline can function continuously at temperatures up to 55°C, making it an ideal choice for extended monitoring in industrial settings.

4. Flexible and Easy Installation

The pipe system is designed with a minimum bending radius of 0.5 meters, allowing for easy installation in tight spaces. It can be installed across a maximum continuous length of 100-130 meters, providing flexibility and adaptability for various industrial setups.

Technical Specifications

| Project | Specifications |

|---|---|

| Heat Tracing Belt | Constant power parallel type, reinforced explosion-proof heat tracing belt, 60W/m. Silver-plated copper busbar (19*0.41) with 4 layers of insulation. |

| Heating Element | Imported copper nickel alloy wire wrapped with PFA and glass fiber, alkali-free glass fiber braid, PTFE extrusion. |

| Sampling Tube | Dual PTFE pipes (Φ8), Teflon tubes with ultra-low volatilization to prevent sample contamination. |

| Double-Sided Aluminum Foil | Single-layer wrapping, designed to provide additional heat insulation and protection. |

| Nano Fireproof Layer | Withstands temperatures over 450°C, forms a hard protective shell for added safety in extreme heat or fire conditions. |

| Glass Fiber Belt | Two-way wrapping of 50g/m² glass fiber, providing extreme insulation for both temperature and environmental resistance. |

| Outer Sheath | PVC sheath with cold resistance down to -25°C, designed to protect the inner layers from environmental wear and tear. |

| Outer Diameter | 42±2mm |

Applications

The CEMS-PRE350 heat tracing sampling compound pipe is highly versatile and can be applied in various industrial sectors:

1. Industrial Emission Monitoring

The CEMS-PRE350 is primarily used in industries that require continuous emission monitoring systems, such as power plants, chemical refineries, and waste incineration facilities. The corrosion-resistant design ensures reliable performance even in environments with harsh chemicals and fluctuating temperatures.

2. Chemical Processing Plants

This compound pipe is also suitable for use in chemical processing plants where high levels of acidity, alkalis, or volatile chemicals are present. Its corrosion-resistant materials and heat tracing capabilities make it ideal for sampling hazardous gases or liquids.

Benefits

1. Enhanced Durability and Longevity

The multi-layered construction of the CEMS-PRE350 ensures long-lasting durability. Its robust design not only resists chemical corrosion but also withstands extreme temperatures, reducing the need for frequent maintenance or replacement.

2. Improved Safety and Accuracy

With its explosion-proof design and high-temperature insulation, the CEMS-PRE350 offers enhanced safety in high-risk environments. The use of PTFE and other high-performance materials ensures that the integrity of the samples remains intact, providing accurate readings crucial for environmental compliance.

3. Cost-Effective Operation

The extended life span and reduced maintenance requirements of the CEMS-PRE350 make it a cost-effective solution for businesses looking to lower operational costs. Its efficient heat tracing system reduces energy consumption, contributing to both environmental sustainability and cost savings.

Conclusion

The CEMS-PRE350 heat tracing sampling compound pipe is the ultimate solution for industries that require reliable and durable environmental monitoring. Its advanced features, including exceptional corrosion resistance, long-term high-temperature operation, and flexible installation options, make it the perfect choice for emission monitoring systems.

For industries looking to improve the accuracy and reliability of their environmental monitoring systems, the CEMS-PRE350 offers a powerful, long-lasting solution that ensures both safety and cost efficiency.

Contact us today to learn more about how the CEMS-PRE350 can meet your industrial monitoring needs!

PRE-WS2020 Series – The Ideal Solution for Comprehensive Water Quality Analysis

Vortex Flowmeter PRE7200 Series- Flow Measurement

CEMS-PRE100 Integrated Temperature and Pressure Transmitter